Gather ’round, me hearties, and I will tell ye the tale of the Rusty Sabre of Portugal. Aye! ‘Twas a Royal Sabre!

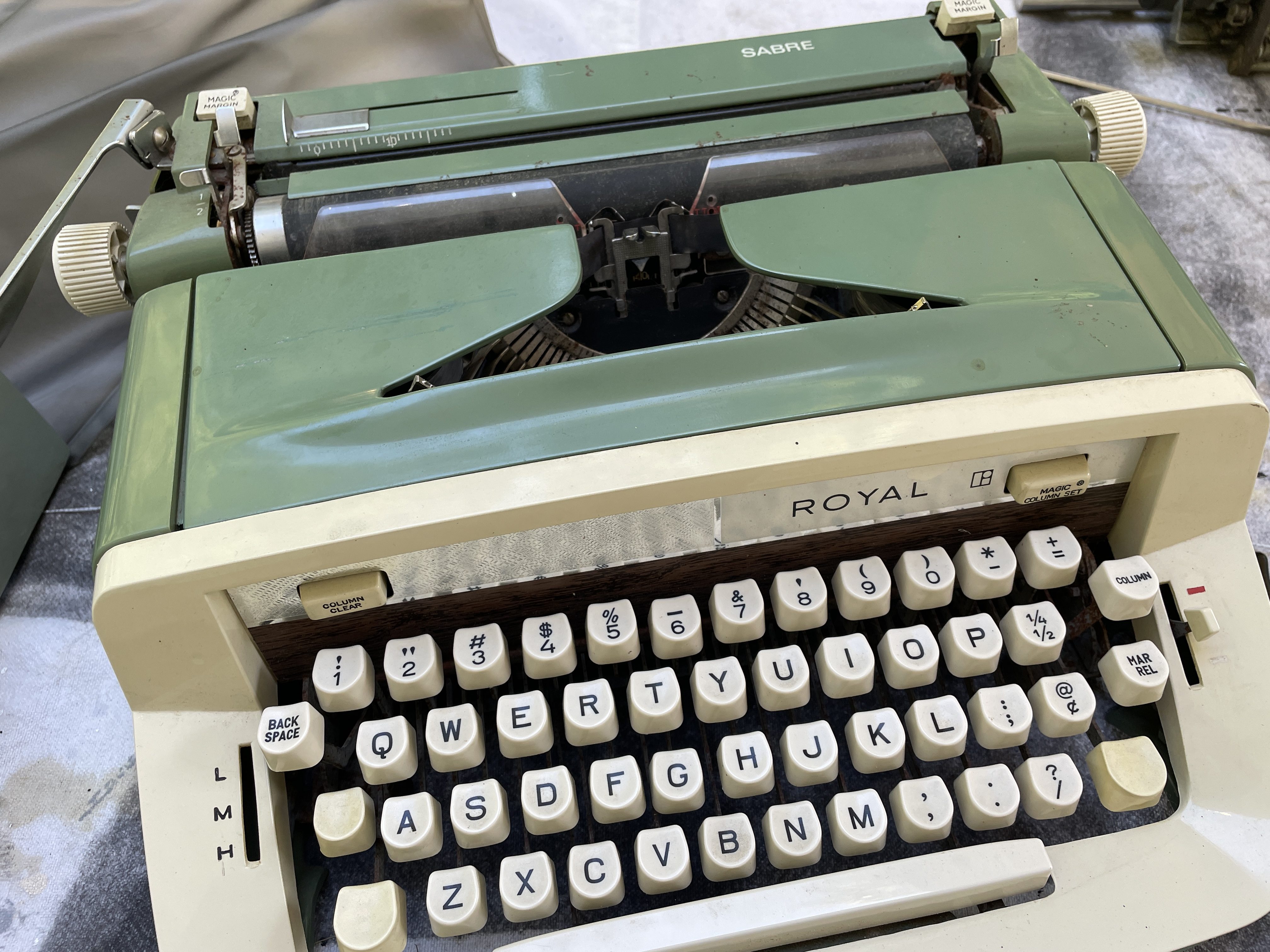

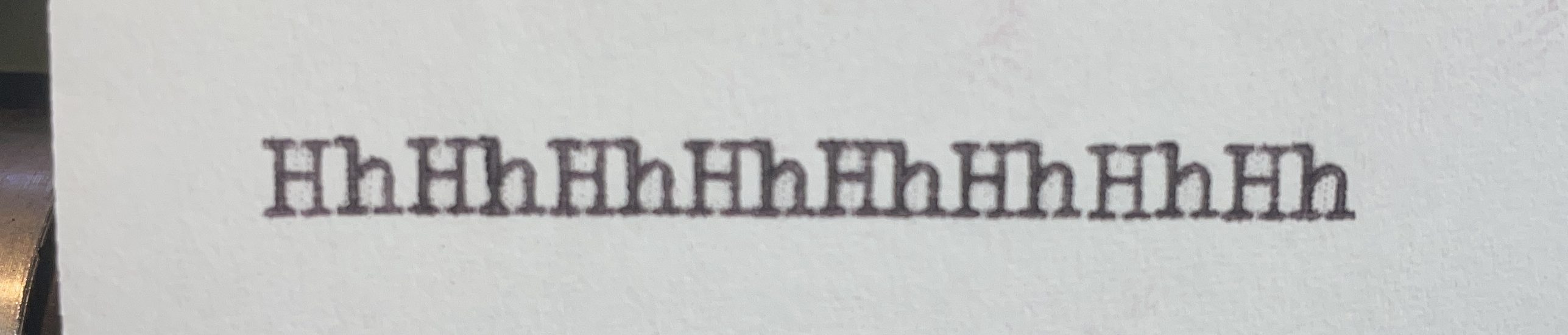

This isn’t a pirate story, but the story of a 1979 Royal Sabre (SN#: SB-9198379, made in Portugal) that was rusted solid. It’s still rusty, but it works now!

Last weekend, I went over to Stephen and Monica B’s place to drop off their Hermes 2000 and Hermes Rocket that I had worked on.

I got a chance to check out their extensive collection. Ross, another typospherian who lives nearby, dropped in to say hi. Here are Ross and Stephen checking out Stephen’s Blickenderfers:

Stephen and Monica convinced me that I should take home some project typewriters, so I came back with the Royal Sabre, a 1967 Olivetti Underwood 21 with a bad carriage release, and a distressed 1952 Underwood Rhythm Touch.

The Rhythm Touch is one of those stunt clean-ups I like. I enjoy taking something that looks bad and making it work. And I try to make it look better. Stephen had found this Underwood in a shed at his father’s house when he was cleaning up. I understand that its roots are at the FBI. This G-man has seen better days. It’s very dirty, frozen solid, and the spacebar is just hanging there. The paint is coming off, so if I can get it functional, I may paint it black or some fun color.

The heart wants what it wants, or else it does not care – Emily Dickinson

So back to the Sabre. Monica and Stephen were unsure what to do about it. It was super cool looking (green!) but completely dysfunctional because of pervasive rust. I told them I would do what I could.

Good thing the shell is mostly plastic. It was sooooo rusty and corroded on the inside:

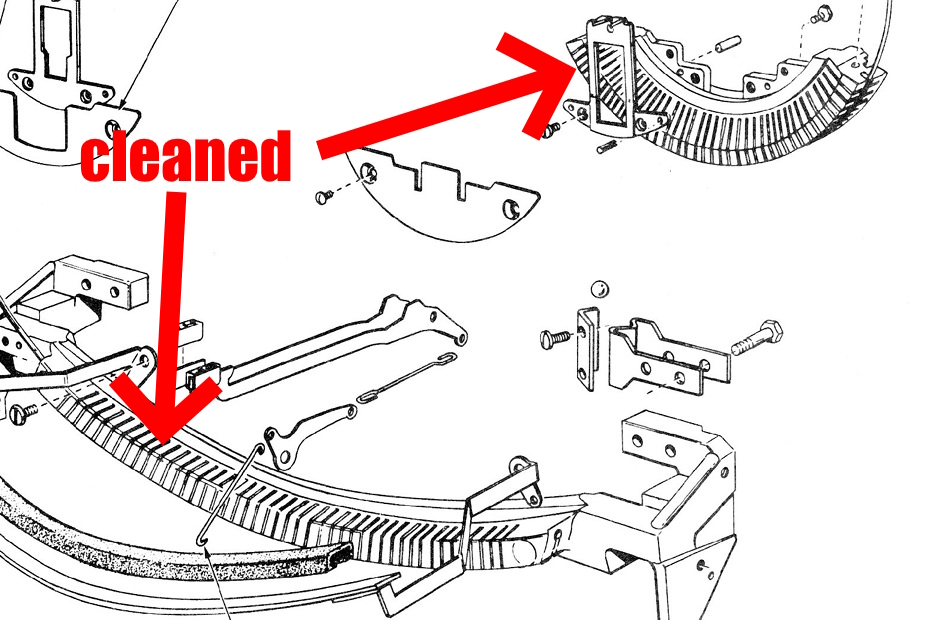

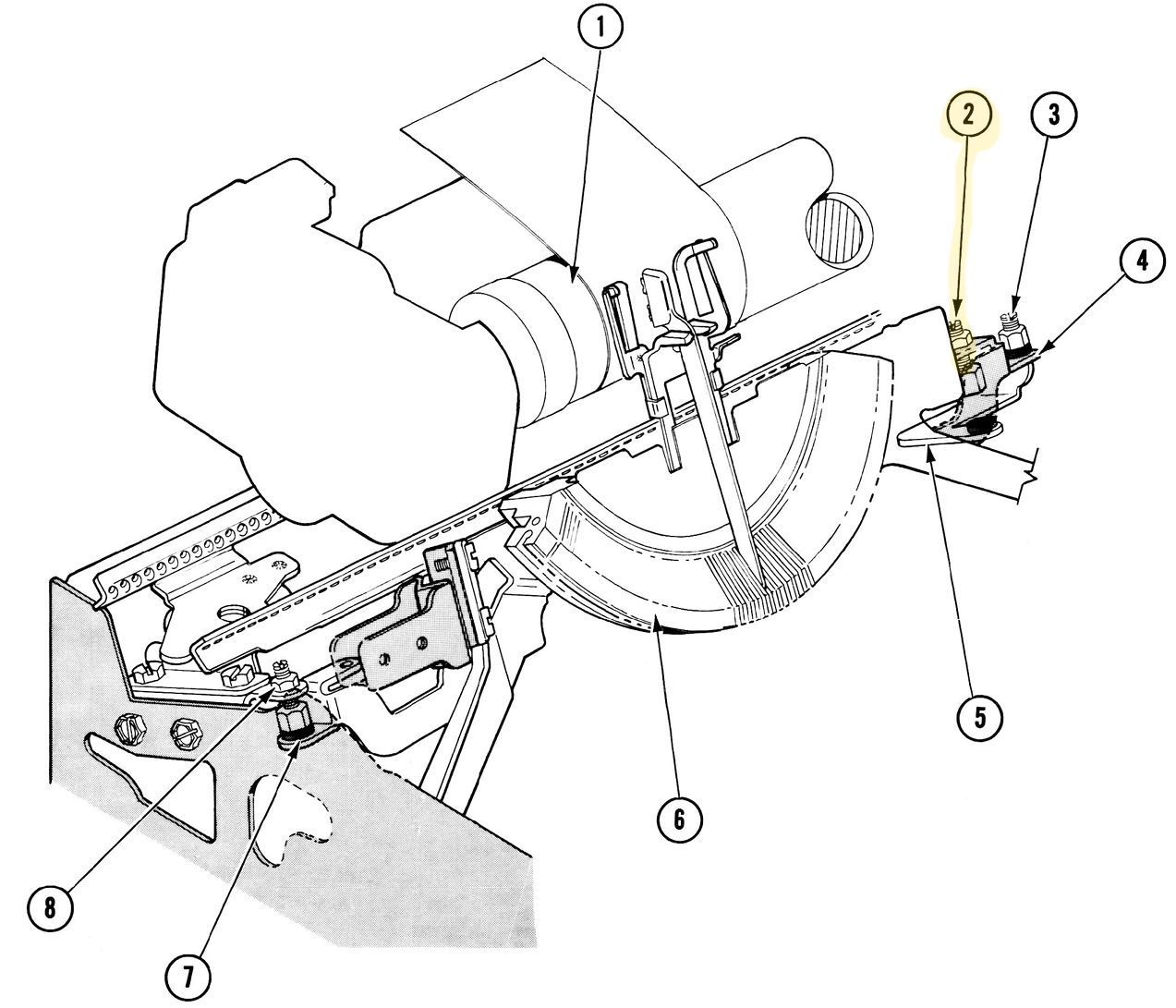

I am fortunate to have the TWDB Operation OOPRAP Sabre repair manual in PDF. I found it helpful:

The Sabre’s typebars were rusted solidly in place. I have never experienced a segment so frozen. I worried that I might break a typebar or bend a link trying to get it moving.

I blew out the cobwebs, put some penetrating oil on the segment, let it sit, followed up with mineral spirits, and slowly got the stiff bars to move. I worked on not only the typebar segment, but also on the sublever segment as well. So. Much. Rust.

Once I got the typebars moving (grudgingly at first), I worked on the variable. The variable was stuck so that the platen spun freely and wouldn’t ratchet. I’ve seen this before on an old-timey 1930s Royal standard. Fortunately, Royal didn’t change the mechanism much through the years. Here’s Duane working on a Sabre with the same variable / ratchet issue:

I took the platen out (which was not easy because the platen rod was rusted into the platen channel) and found that the triangular plunger part on the end of the platen (The Line Space Cylinder Clutch Assembly) was rusted solid and stuck down. I pried the part out, scrubbed off the rust, cleaned, lubricated with Tri-Flow until the plunger piece didn’t bind in the shaft holes and went boing-boing-boing the way it should.

Stuck and rusted solid

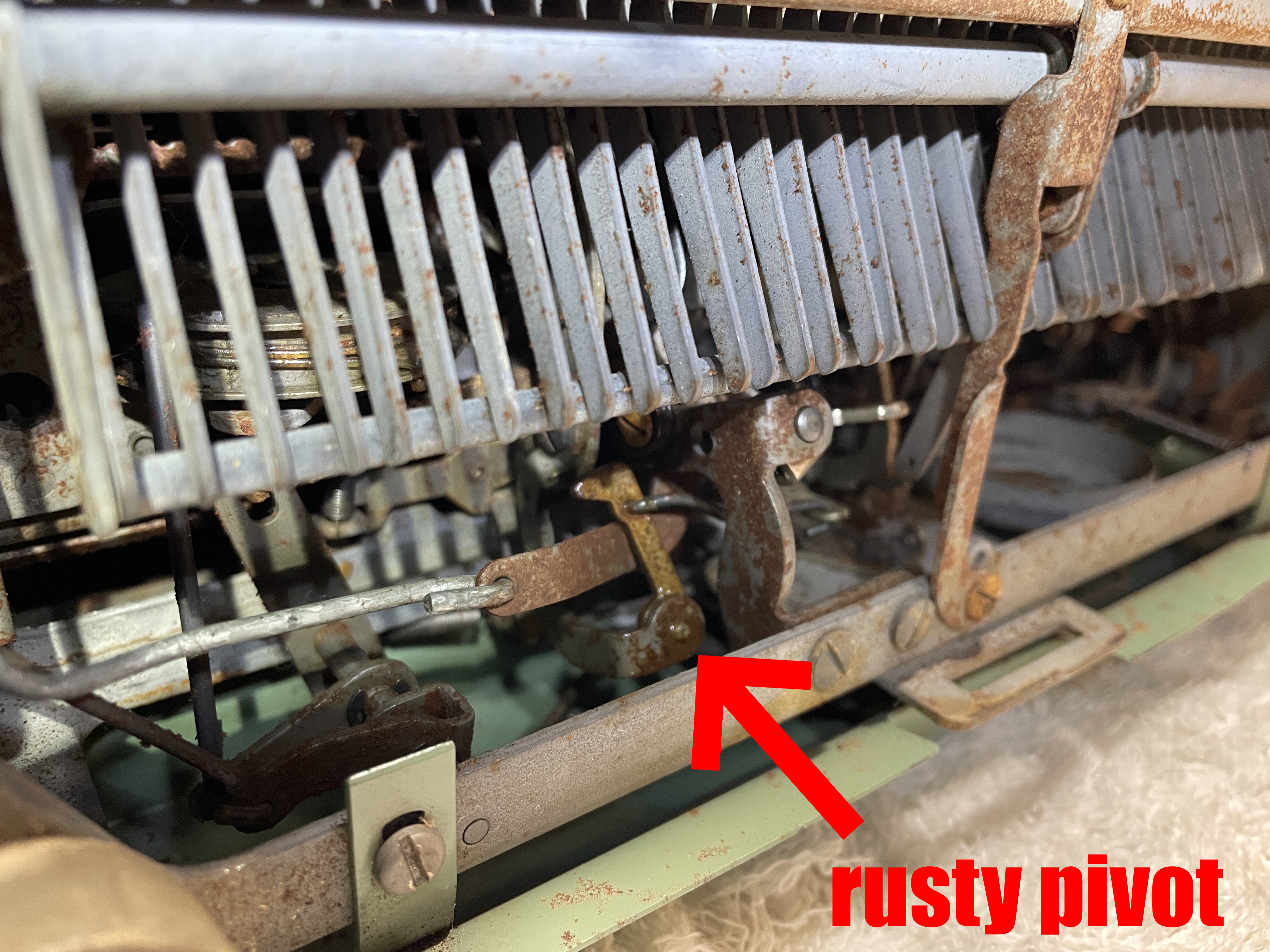

Another problem was that the line lock would stick after engaging and the only way to free the carriage was to hit the margin release key. Here is Duane describing a line lock issue on a Royal portable caused by parts binding on one another:

My problem was rust in the pivot points. Here it is, rusty but functional.

I scrubbed off the rust with a brass bristle brush, worked the mechanism by hand, cleaned with mineral spirits, and lubricated with Tri-Flow, and the line lock began to behave properly.

Another thing that drove me bananas was that the bell wasn’t ringing on this Royal Sabre. What I found when I investigated was MORE RUST. The rusty little tail of the bell trip (that dangles from the right margin stop) was rusted into the “up” position. Once again, I worked it by hand, cleaned with mineral spirits, and lubricated with Tri-Flow. The bell trip began to swing freely. Ding. Ding. Ding. I love that sound.

I also had to clean and lubricate the Magic Margins and the tab system. I had problems getting the metal cover plate off the back because it was rusted on (!)

My process for just about every piece of this machine was this: work the rusty pieces by hand until loose, scrape off rust, clean with mineral spirits, then lubricate with Tri-Flow.

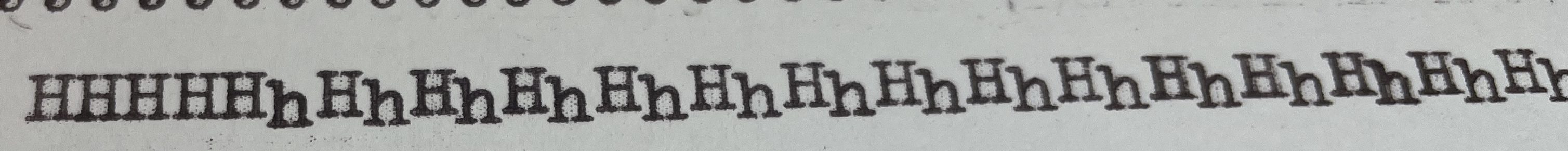

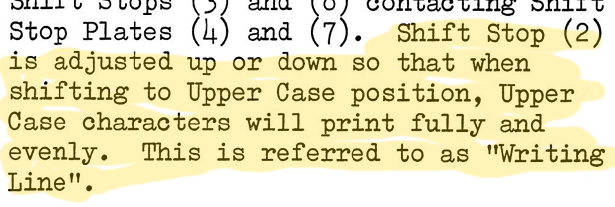

I noticed while testing that the shifted letters were a little high.

I watched Duane’s video on adjusting the shift on a QDL, but unlike a QDL, there is only one shift adjustment screw on the Sabre.

Per my Sabre repair manual:

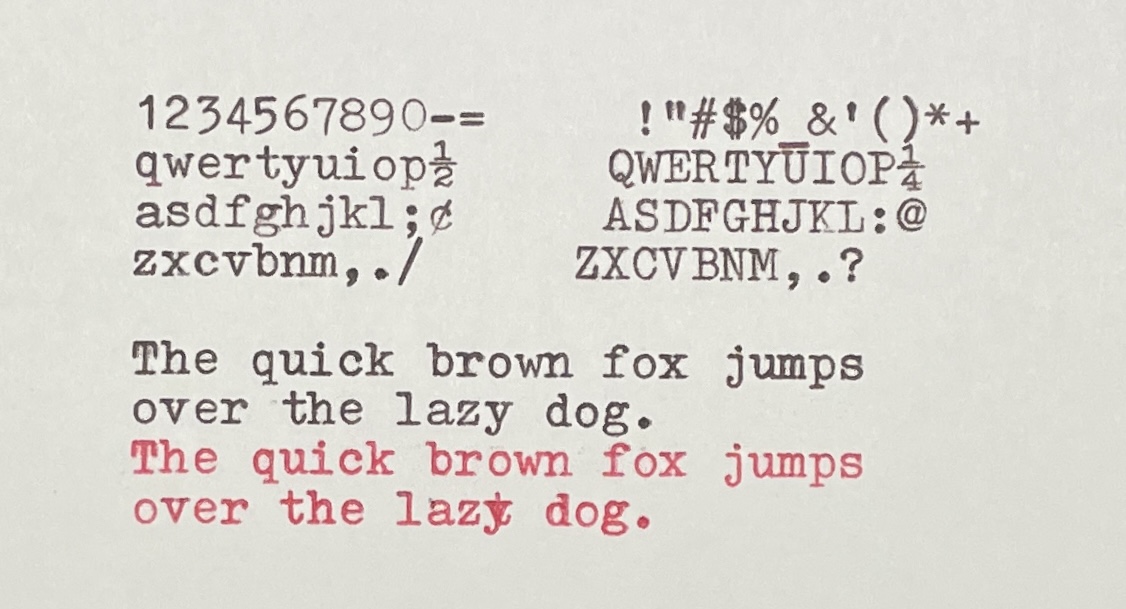

I used a7/32″ nut driver to loosen the lock nut and then backed out the adjustment screw about a turn and a half. I tightened the lock nut down. Looks good, everything printing fully and evenly:

Now that it’s cleaned up, I think this is a pretty swell machine. You really can’t tell that it’s crawling with rust on the inside. I’d like to try a typing comparison between a U.S.-made Safari and this Portuguese Sabre.

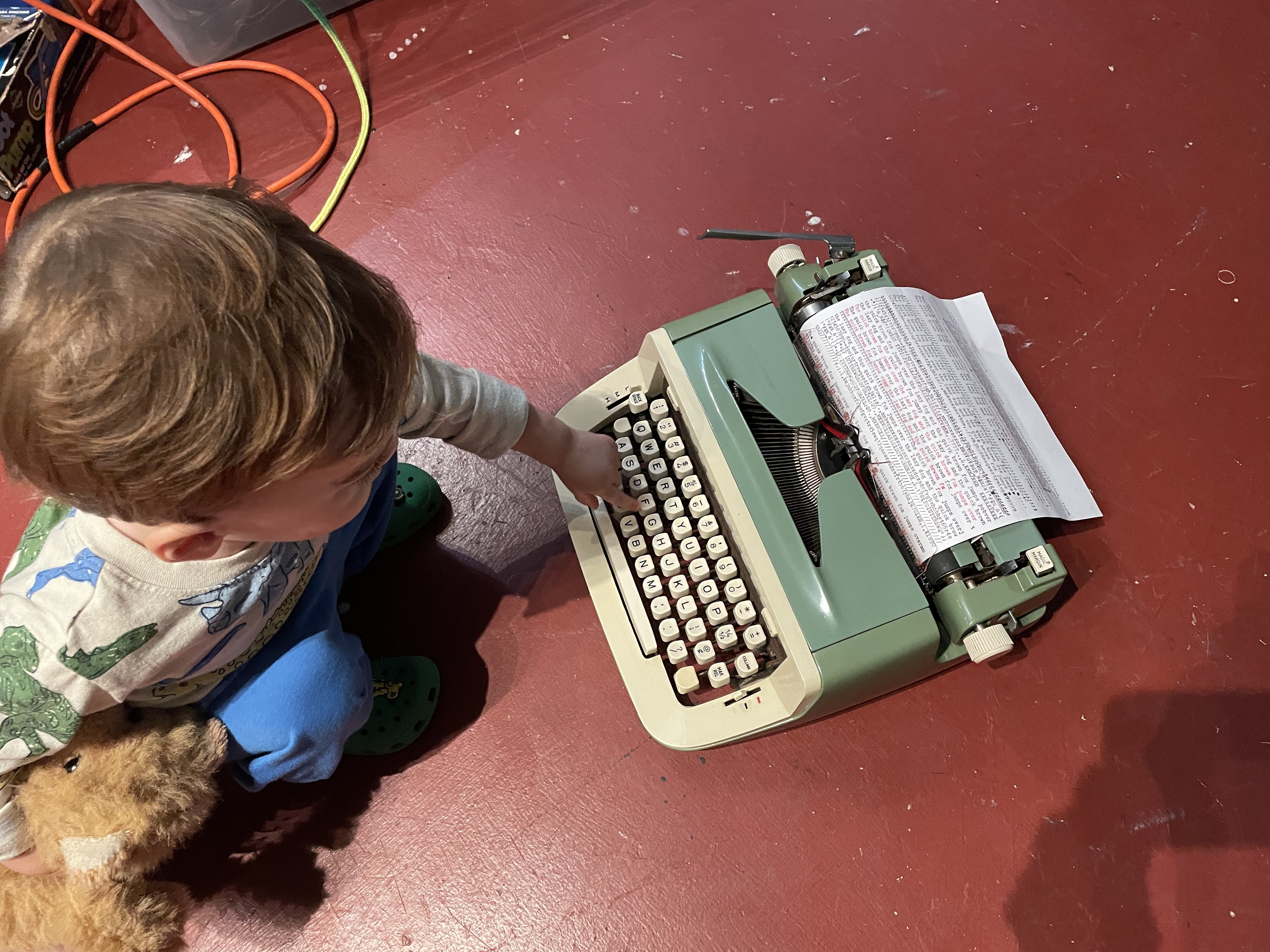

Here’s a photo of my young apprentice doing some quality control testing.

Nice work on the Sabre. I had one of those, not rusty, a long time ago. I gave it away as a prize at a Type-In.

I did have a rusted solid H3k that I soaked in Evap-o-rust for a few days and it came out, as expected, rust free with a nice finish, Evap-o-rust leaves a nice coating behind when the rust is dissolved. A cleaning of some parts and the machine has been working for years.

Good luck with the Rhythm Touch. I hope you get it working. They are very nice typewriters to use.

LikeLike

I like Evaporust as well. The only hitch is that rusty pieces need to be submerged. I’d like to try a wipe-on rust converter for rusty typewriters.

The Rhythm Touch is coming along really nicely and I’ll blog about it soon.

LikeLike

Young Apprentice sure is growing fast! (:

LikeLike

Can’t wait until the Young Apprentice is old enough to help me with those typewriter repairs that need three or four hands (eg drawband repairs).

LikeLike

Wow, kudos to you for dealing with all that rust! There are times when I wish I could just strip the painted parts off a machine off and dunk the rest in degreaser and rust remover, but hey, more work is more rewarding I suppose. 🙂 The closest I’ve come to that is this machine: https://typewriterdatabase.com/1938-diplomat-4.19929.typewriter . It had rust on all the visible metal surfaces that I patiently cleaned off because I had never seen a Diplomat 4 listed and the shell looking like it went through a WW2 bombing (which I mostly kept as is) hints at a story that made me want to save it for the future. I still need to replace that platen knob though.

LikeLike

Your Diplomat looks much better after its cleaning. That is a rare Olympia rebranding – have not run across a Diplomat before.

LikeLike

Guess if I make it to a NoVa type-in the Diplomat will be making the trip! I better figure out that knob replacement!

LikeLike