Monica and Stephen are local collectors who have many typewriters that are just my type, my personal kink being dysfunctional machines that need a lot of work.

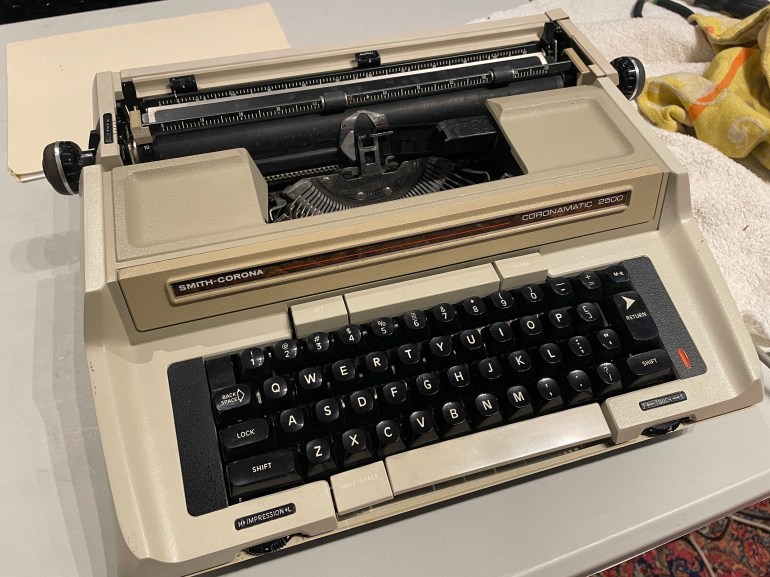

Farhad’s Coronamatic 2500

A local typewriter enthusiast named Jean asked me to look at her 1980s Coronamatic 2500’s nonfunctional “N/n” key. Jean is a persistent typist, and she loves this typewriter so much that she was making do using double “l” with a handwritten diagonal in place of “N/n” when she typed on it.

Missing Spring, Missing Handle: Royal Futura 800

I recently worked on a 1960 Royal Futura 800 and became familiar with what my research says is a common problem in Futuras: ribbon vibrator forks that flop open allowing the ribbon to migrate out of the ribbon vibrator while typing.

The Rusty Sabre

Gather ’round, me hearties, and I will tell ye the tale of the Rusty Sabre of Portugal. Aye! ‘Twas a Royal Sabre!

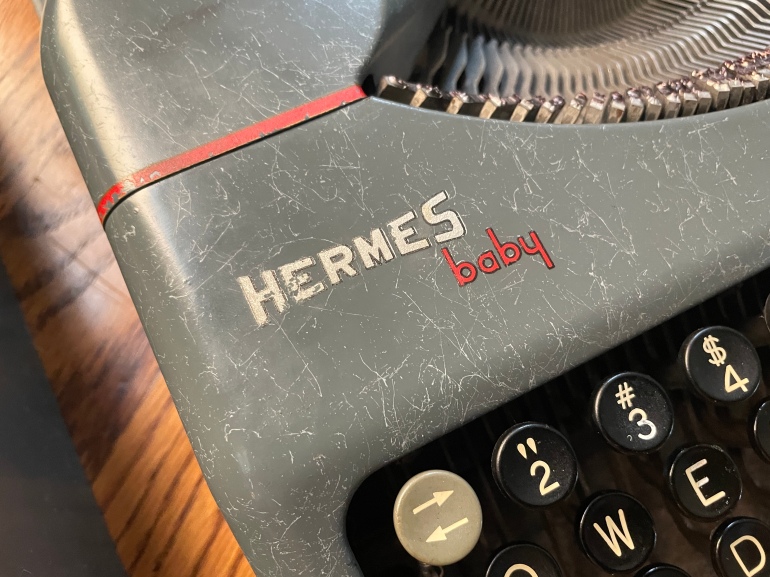

My Summer Vacay with a Hermes Babay

Summer got away from me, and here it is mid-August already. In June, I drove out to the wilds of the DC suburbs where I picked up a couple typewriters in need of some attention. They are owned by a local typewriter enthusiast, Suzanne. One was a 30+ lb behemoth, a KMG with a tabulator issue that I fixed up, and the other was a teeny 1943 Hermes Baby.

Good Enough Is Very Fine: Royal KMG Tabulator Issue

I headed to a nearby suburb a couple weeks ago to pick up a Hermes Baby with a carriage bail issue. Owned by local typewriter enthusiast Suzanne, the Baby needed a spring replaced in a procedure that sounded much more complicated than I would have thought. Replacement involved something about special tools and torsion springs. 😬

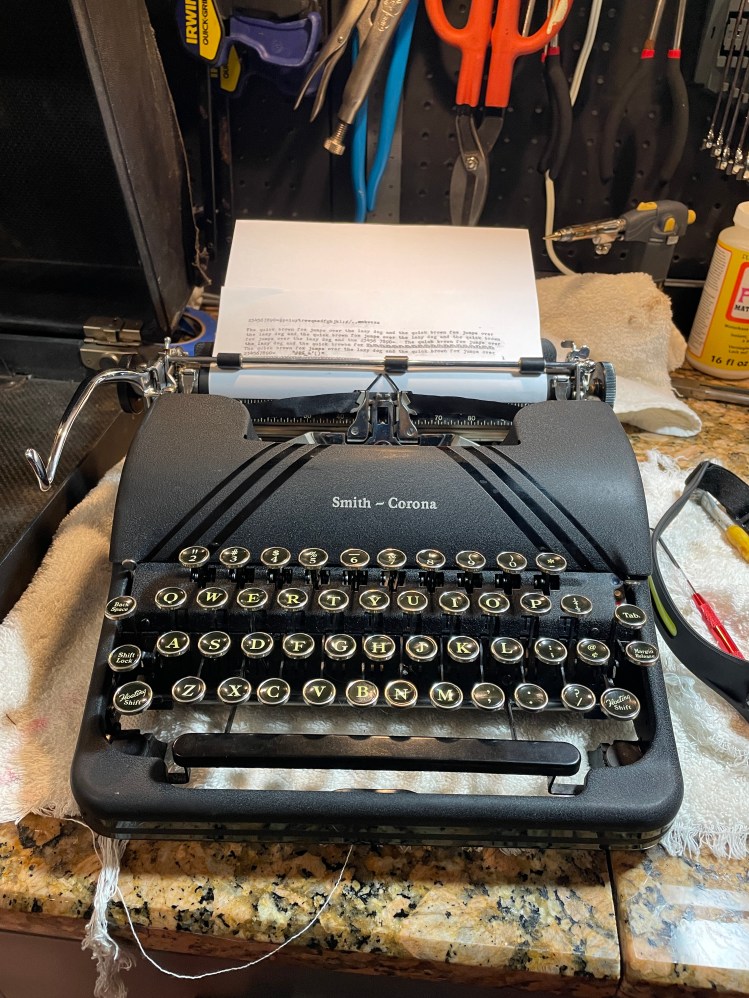

Black Beauty: Royal De Luxe Portable

A local typewriter enthusiast named Ross has a stable full of Royal portables. These fine fillies are spirited creatures, but after 70 or 80 or 90 years of being ridden hard and put away wet, many need attention. I recently worked to fix some nagging issues on a 1950s QDL and a 1939 QDL, and he had another 1930s De Luxe that I looked at. Continue reading

Mother and Daughter: Hermes 2000 and Hermes Rocket

Monica and Stephen are a delightful local couple who are really into typewriters. They not only collect, but they organize type-ins and bring people together for typing fun. I was a little late to the Monica and Stephen Party, but I’m so glad to know them now. Good people.

To the Dogs: Royal Quiet De Luxe

We have a couple special books for our grandson on the mantel at our house. One is called Bad Hair, and it’s just a collection of weird hair photos from vintage barber magazines—my grandson finds it fascinating. Another favorite is a book of dog photos taken by Elliott Erwitt. We handle these two books very carefully (soft-soft—no chewing!) and examine the pictures.

Escapements and Carriages: Purple Porto-Rite and Royal QDL

I recently attended a type-in at a local public library. Two members of the Mid-Atlantic Typewriter Collectors Group, Monica and her husband Stephen, organized the event. They’ve done this a couple times in the past, and they always get a good crowd of local enthusiasts, library walk-ins, and kids.

Soft-Soft: Underwood No. 4

Since my son and daughter-in-law have moved closer to me, I have been busy in Grandma Land chasing a newly-walking terror intent on finding the most fragile, most dangerous items to crush or mouth.

New Punch List: Olympia SG1

I finished up the Olympia SG1 project and patted myself on the back. Nailed it! Job well done! I fed some paper through it and started some long-form typing—a letter to RRTM—and that’s when the SG1’s residual issues became apparent. There would be no kicking back and cracking a celebratory brewski (ein bier) yet. I saw more work to be done.

Classy Dames: Olympia SG1 and Husqvarna 6430

Last week, I was again drawn helplessly to the McDonald’s in Germantown, MD. The powerful gravitational force of a large, dysfunctional Olympia SG1 pulled me into its orbit and brought me to a parking lot in suburban Maryland during a heat wave.

‘Tis a Gift

I’m back from California and a month-long visit with my new baby grandson. My report: he’s very perfect, and like many babies, he resembles Charles Laughton. Also, relative to his tiny body, he has enormous hands, and I foresee a career as a piano player or a typewriter mechanic.

The Weird: Hammond No. 2

I’m a very normal person. Like other very normal people, the Weird makes me queasy, and I generally don’t seek it out. However, sometimes the tentacles of the numinous reach for me, and I am pulled into another layer of reality outside my current one.