A local collector named Michael has become my go-to source for broken typewriters. He collects the good, the bad, and the indifferent—he loves them all and welcomes them with open arms and no judgement. When he told me he had an Olympia SM4 with a flying carriage, I began to salivate reflexively. Nice machine. Interesting problem.

In my career as an amateur typewriter tinkerer, I have seen sliding carriage issues before. These carriages won’t catch and stay put, they fly off to the left. I have fixed a few of them. I have found gummy, rusty, or broken parts to be the culprits. Here are the greatest hits:

However, I have known defeat.

As I thought about that exasperating 1956 Underwood De Luxe, I stopped myself and felt a novel feeling wash over me. As tantalizing as Michael’s ailing Olympia SM4 is, I shouldn’t bring home another broken typewriter when I have a perfectly nice broken typewriter in the house already. Restraint, that’s what this strange new feeling is called.

I found the Underwood De Luxe Shelf King upstairs drinking a protein shake and watching dash cam YouTube. You beautiful bum! Easy on the eyes but lazy to the bone. You have such a nice typeface and yet you do nothing but sit around the house and look pretty.

I brought the Underwood De Luxe downstairs to the garage workbench and considered it. Dusty and unused from its easy life on a shelf, it’s comically plumpy with Michelin Man bulges and gold accents. This deliriously silly and over-the-top design was soon to be replaced by mod Belt Buckle Underwoods and then that thing with Olivetti happened.

I had to remove the carriage to understand what was going on here. A couple years back, I had cleaned and poked and prodded the Underwood De Luxe Quiet Tab to no avail.

Keep in mind that removing the carriage from most typewriters is a last resort. For the casual hobbyist like me, removing the carriage is an act of desperation, what rash people do when they throw spaghetti at the wall and hope something sticks.

But this Underwood portable is a steel fortress. All its mysteries are hidden behind tall gates. I would have to remove the carriage to get at its secrets.

My reasoning was that since this typewriter was nonfunctional, there was nothing I could do to it that would make it worse. Worse case scenario: put it back together and it would continue its life as a Shelf King.

So how do you take the carriage off an Underwood portable of this era? Older Underwood portables: you’re in luck! I found a detailed description at Reddit with lots of photos:

Removing the carriage: older Underwood portables

However, this De Luxe is a newer model and starting at about serial number 2,000,000+ when the Underwood Finger-Flite was introduced, the internal workings changed. I would have to struggle along without a roadmap.

I took off the bottom and ribbon covers, but I wrestled with the paper table cover since I couldn’t initially remove the knobs and side cover plates. Rusted 4-spline Bristol set screws on the knob handles defeated me. I eventually got one knob off with a very sharp, very tiny Philips head screwdriver. Good grief.

I finally removed the carriage, and it was kind of embarrassing how much manhandling was involved. In the process, I started peeling things off—the back carriage rail and the tab system—and pretty soon I heard the loose ball bearings landing on the workbench and rolling away.

A member of the Facebook Antique Typewriter Maintenance group called this typewriter repair approach as going into “berserk mode” which is an accurate description of how haphazardly I began to furiously dismantle. Don’t do this, people.

I put the tab mechanism back together as soon as I could. It was wrong, but I figured it out eventually.

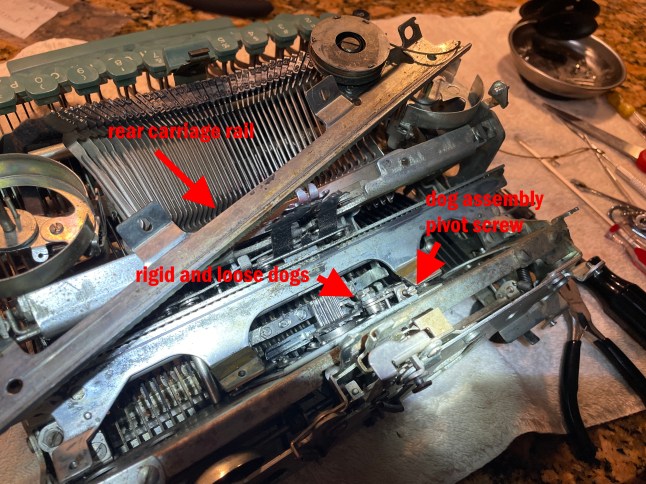

To get at the escapement, I had to remove the back carriage rail to back out the dog assembly plate fulcrum/pivot screw.

I pulled out the long thin rocker fulcrum screw that the dog assembly plate pivots on and pulled out the loose and rigid dog assembly.

The long thin fulcrum screw that the dog assembly plate pivots on.

And there it was, the source of my sorrow:

A broken tooth on the loose dog.

I opened up my 1955 Ames General Catalog (thank you, TWDB Operation OOPRAP):

Here’s part 4H210, flipped. It should have a little pointed projection that hops into the escapement wheel and stops the carriage from flying willy-nilly. That sharp little tooth is broken off on my dysfunctional Underwood De Luxe.

I considered my options:

- Buy a parts machine off eBay. Ha-ha. No.

- Email Trevor at TB Writers Plus and see if he has a loose dog for a 1950s Finger-Flite style Underwood portable. I felt shy about asking Trevor since he is running a repair shop and would likely need that rare-ish part himself at one point.

- Join the Facebook Typewriter Parts and Accessories Exchange and see if anyone has a parts machine that has an intact dog.

- Solder a tip on the broken dog. Here’s an interesting video of soldering an escapement on a Harris Visible.

- Put it back together and live with a lazy Shelf King De Luxe

- J-B Weld a new tip on the broken dog

Yeah. J-B Weld. That might do it. I did a test with a washer and a nut and it bonds nicely if there is enough surface area. It’s mold-able and cut-able before it cures completely.

I sanded the broken dog and cleaned it with denatured alcohol. I created a “stage” from a plastic lid and sprayed it with silicone spray so the J-B Weld wouldn’t adhere. I mixed up a small batch of slow-curing, super-strong formula J-B Weld and blobbed it on.

After 24 hours, I sanded the part and put my dog assembly back together. The loose dog looked too big, but I figured I could sand it down and reshape it if necessary.

I re-inserted the dog assembly plate using sticky grease to hold the rocker compression spring in place while I fiddled with the dog rocker assembly and reinserted the fulcrum screw. I flushed out the grease once I had the plate seated.

I hand-tested the escapement once the dogs were in place, but the J-B weld loose dog tip was a little too big and interfering with the rigid dog. I pulled it out and sanded a bit more until it was this shape:

The dog assembly went back into the machine. I again hand-tested the escapement, and it seemed to step properly. It was time to get the carriage back on and try typing.

The four carriage ball bearings on this Underwood De Luxe run independently like those on a Royal portable with small star-shaped bearing retainer pinions around each ball bearing. In fact, Royal portable pinions and Underwood portable pinions are identical in size and shape and both use 1/4″ ball bearings.

In the 1950s, Underwood got rid of carriage bearing “trucks” and ended up with this fiddly, exasperating system of four independent ball bearings surrounded by pinion retainers. I figured it was time to hunt for the Straw Video. I found it.

Chicago Typewriter has an ingenious method for dealing with Royal portable carriage ball bearings and their pinions. He uses a straw as a tool for bearing placement during carriage installation.

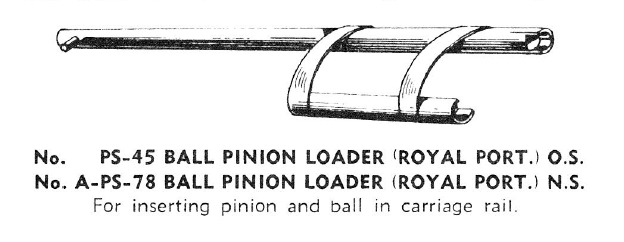

In the old days, before the straw hack, you used a tool called the “Ball Pinion Loader” A.K.A. “Carriage Ball Feeder” like this on Royals:

These are instructions for a Royal portable. I don’t have an Underwood pinion loader or Underwood instructions, but I do have plastic straws, so I went to work.

I worked on a light-colored drop cloth for which I was glad. I kept dropping ball bearings and pinions. I found that a magnetized screwdriver was very helpful in drawing out bearings and pinions that had dropped into the guts of the machine.

I kept the rear carriage rail on the machine very loose which helped with ball bearing and pinion loading. The procedure was still a huge pain in the neck. I kept dropping ball bearings and pinions.

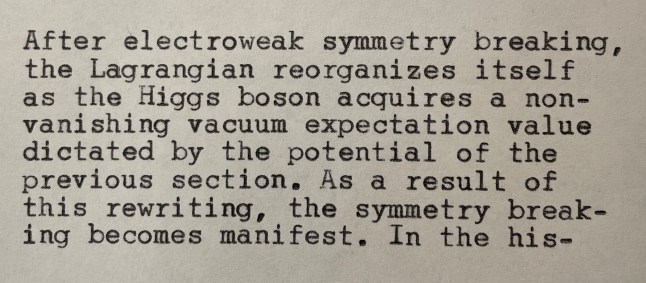

I finally got the four ball bearings in, tightened up my rear carriage rail, and tested. The carriage seemed to glide nicely. I tried some typing.

Ah, yes. What a swell typeface! This one is called “Continental”.

After some trial and error, I got the tab system reinstalled properly.

I put the cover plates back on. Looking good, Underwood De Luxe. Who’s a good dog?

The Underwood De Luxe was typing away happily, but in the back of my mind I worried about the durability of that J-B Weld dog tooth. The J-B Weld tooth sanded a little too easily.

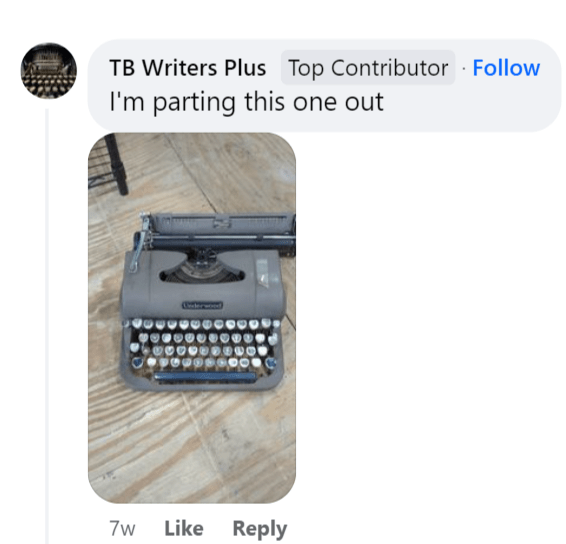

I have recently joined the Facebook Typewriter Parts and Accessories Exchange. This is a closed group, and you have to request admission, but they approved my request quickly. I saw this post:

Oh, heck. That might be the ticket. I think this Underwood portable has the newer style Underwood escapement. I guess I will bother TB Writers Plus after all.

I emailed Trevor. He plans to dig through his parts machine and see if he has a loose dog of the style I need.

After I sent the email, I heard a click-clack-ding from the garage. I found the Underwood De Luxe in the garage typing by itself.

What’s going on here, Underwood De Luxe? In all the years you’ve been with me, you’ve just sat around the house watching dash cam videos and didn’t type a thing—

What?

But—

Are you evil?

What? But I’ve had you for five years and you have been mute the whole time—

But—

And suddenly the De Luxe Quiet Tab went silent. Letters piled up and suddenly the carriage slid to the left. Uh oh.

I removed the carriage once more. Here’s a rundown of what I did:

- Hooked the drawband onto rear carriage rail

- Removed the left carriage knob

- Removed the side cover plate around the knob

- Removed the rear paper table cover

- Removed the rear tab mechanism

- Loosened six rear carriage rail screws

- Pried out four carriage ball bearings and pinions with rear rail loosened

- Lifted the carriage up and out

I pulled out the dog assembly and assessed the damage. We flew too close to the sun, the De Luxe and I. My J-B Weld tooth was sheared off.

While I waited to hear back from Trevor at TB Writers Plus about a replacement dog, I attempted an unsuccessful solder repair. If you are parting out a plumpy 1950s Finger-Flite style Underwood portable with serial number 2,000,000+, hit me up in the comments. I’d love to get this thing running again.

I modeled the loose dog in Tinkercad and submitted a 3D printing request to the Arlington Public Library. A 3D print in PLA is probably not going to be durable enough, but I just want to see it typing again while I research my options. To be continued…

Your experience triggered so many flashbacks of a Finger-Flite Champion that once barged into my front door and couldn’t leave fast enough. An invaluable learning experience, but nevertheless one that I won’t willingly jump back into any time soon. But I understand the motivation, especially for that typeface! (As it so happened, I noticed those peculiar nuances on the Q and 2 and those wide open g‘s and p‘s on, of all things, a desktop Underwood Rhythm Touch, and boy was I happy. Continental on something more solid than the portables of this era? Of course I jumped at it.)

Funnily enough, I explored JB Weld on a chipped dog for an Alpina, and just like you, I found it to be easy to use but, sadly, low on durability. I’ve yet to find an application that resulted in something satisfactory. Live and learn, I suppose. Keep us posted on the resolution, and thanks for offering such great resources, as always!

LikeLiked by 1 person

I’m thinking about reaching out to a welder I know and getting his opinion on welding a tiny blob of metal onto the dog. I could file and sand the blob into shape, but I wonder if that would be a durable solution.

LikeLike

You know, I actually think it would be worth contacting someone who 3D prints metal parts. I knew someone who did that in the Dallas area but am not sure if there is an equivalent option here in Virginia. My feeling is that nothing will ever be as good as a new, solid piece, and in this day and age, it seems anything can be reproduced if the original or the schematics are available.

LikeLike

I agree. I’m thinking about sending my file to SendCutSend, a laser cutting service:

https://sendcutsend.com/

I’m having a 3D part printed in PLA and if I have sizing and fit correct, I might send the file to SendCutSend.

LikeLike

This looks really promising! I do hope they can offer you a superior solution if you choose to go this route.

LikeLike

you are opinionated ……

LikeLike

😀

LikeLike

I’m fortunate to have one of these retro looking 1950s Underwood portables that works. Nevertheless, it’s action has much to be desired. Beware of these as our community has yet to find a repair manual except for your blog 🙂

LikeLike

I’m hoping that some day a service manual for these will turn up. In the meantime, I’m just going to document in detail for future reference.

LikeLiked by 1 person

I’m pretty sure I have a 1950s Underwood Universal quiet tab parts machine, I’ll check and let you know. Great blog post.

LikeLike

Oh wow! That would be great. I think that after serial number 2,000,000, the escapement mechanism changed in Underwood portables. An Underwood with this newer escapement/dog assembly is what I need.

LikeLike

Looks like I got rid of my parts machine but I am asking around, I’m a moderator of the Facebook Typewriter parts group so I’m searching through the archives from previous posts, Gerren (Gerren Hot Rod Typewriters) might have one in Spokane, just waiting to hear back from him.

LikeLike

Thank you so much for checking!

LikeLike